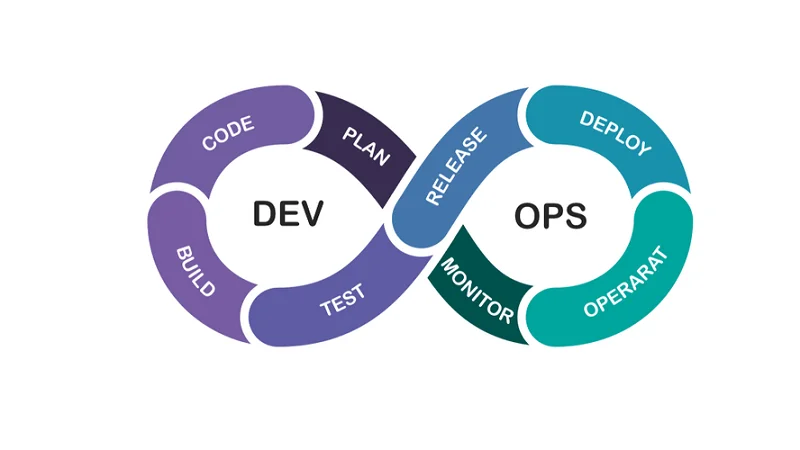

Simply divide the total variety of hours from Step 2 by the number of property in your group from Step 1. Standardizing your main growth processes is the start line https://www.globalcloudteam.com/, however the ending level, as a rule is automation. Standardization might get you midway there, however automation will take your team to the subsequent degree. So many organizations nonetheless opt to use guide strategies for testing and deployment.

In this MTBF definition, it is also important to stress that the MTBF formulation focuses on unplanned maintenance solely. It, subsequently, does not take into account scheduled maintenance or deliberate upkeep, which can include aspects such as inspections, recalibrations or preventive half replacements. MTBF, in contrast, measures the length of time earlier than an asset must be repaired. By the identical token, if your information only covers a quick time frame, your MTBF results most likely won’t accurately represent the asset’s true situation. Using a CMMS ensures that you’ll at all times have access to reliable and accurate knowledge.

In the medical system trade, MTBF is used to assist make sure that gadgets similar to pacemakers, insulin pumps and MRI machines meet reliability necessities and don’t pose a threat to affected person safety. Since the formula for the mdt of two elements in parallel is equivalent to that of the mtbf for 2 elements in sequence. MTTF calculations are determined using the next method. Not all failures are equal, so MTBF has more than one variation, every with a unique definition of failure. A tech company supplies cloud storage options and displays the performance of its servers. It desires to calculate the MTBF of its storage servers over the previous yr.

MTBF is instrumental in planning preventive maintenance schedules by identifying patterns in equipment failures. Understanding the standard time between failures allows companies to schedule maintenance tasks at optimal intervals, avoiding unnecessary tasks and ensuring well timed interventions. This not only extends the lifespan of belongings but additionally improves productivity by lowering unplanned downtime. MTBF is carefully associated to several other maintenance metrics, every providing distinctive insights into system performance and reliability.

- Suppose your staff isn’t meeting organizational expectations for MTBF.

- Jonathan writes about asset management, maintenance software, and SaaS solutions in his role as a digital content creator at Eptura.

- One Other upkeep metric is imply time to restore (MTTR), which represents the typical time it will take to restore the uptime of a given component or system.

- Using a CMMS ensures that you’ll all the time have access to reliable and correct knowledge.

- The key phrase is ‘non-repairable asset.’ MTTF calculates the whole lifespan of apparatus.

In the life sciences industry, groups use MTBF to extend reliability and hold equipment performing in optimal situation. Slowdowns attributable to equipment malfunction can injury product batches or trigger expensive delays. Optimizing asset efficiency helps stop these slowdowns and guarantee uniform production. That means that belongings promptly get the repairs they should stay up and running, resulting in a lot less downtime. MTBF is a key metric in industrial settings, the place downtime can derail manufacturing and increase costs. MTBF can even mean time between failures cut back maintenance costs by helping set maintenance priorities.

Skilled Providers

Want to know what is the difference between downtime and idle time? Sign up for our Downtime Publication to get the most recent news in related reliability. This shows us that, even though 25-year-old people have high MTBF values, their life expectancy (service rate) is so much shorter and doesn’t correlate. Get expert upkeep insights delivered straight to your inbox.

Mean Time Between Failure (mtbf): What It Means & Why It’s Essential

Additionally, MTBF is an essential KPI calculation for reliability engineering, particularly in phrases of important belongings. Maintenance engineers typically rely on MTBF calculations when designing security, mechanical, and digital techniques to make sure optimum outcomes. Precisely how impactful are MTBF-informed upkeep processes? We’re speaking concerning the distinction between spending a couple of hundred dollars in maintenance-related bills versus tons of of hundreds of dollars in costly downtime and misplaced production! The price of downtime for even small and medium-sized manufacturing could be as a lot as $150,000 per hour. Non-critical failures or minor malfunctions aren’t categorized as system aborts.

In reality, Mean Time Between Failures is one-half of the formulation used to calculate availability, along with MTTR (Mean Time to Repair). An equipment’s complete uptime may be expressed as MTBF along with MTTR. Collectively, these two metrics are used to anticipate how doubtless an asset is to interrupt down within a sure time interval or how usually a sure type of failure may occur. This complete strategy will enhance total reliability and efficiency. Across all these sectors, monitoring and improving MTBF is prime to sustaining excessive performance and reliability of techniques.

Mtbf Calculation Method Defined

As an averaging metric, measured in mixture, MTBF is most helpful in measuring overall performance and maintenance effectiveness and efficiency. MTBF should not, for example, be used as a predictor of when a bit of apparatus would possibly fail, or when it must be examined. In safety-critical sectors like aerospace and healthcare, improved MTBF can significantly decrease the risk of accidents, ensuring safer operations and better-quality control processes. Reliable tools with larger MTBF helps preserve efficient workflows, lowering downtime and increasing output effectivity.

Moreover, integrating MTBF with Whole Productive Upkeep (TPM) principles permits for sample identification and preventive maintenance, decreasing unplanned downtime. Continuous coaching for reliability engineers ensures that they are geared up to establish points and perform upkeep correctly, further improving MTBF. In upkeep management, MTBF is a key metric for enhancing system reliability and reducing downtime. A larger MTBF indicates a lower chance of failure, which instantly advantages productivity by allowing for higher planning and scheduling of upkeep actions. Reliability engineers and upkeep managers depend on MTBF calculations to develop effective maintenance schedules and manage spare parts stock more Large Language Model effectively. Each maintenance manager and maintenance staff seeks to scale back downtime and enhance the MTBF metric at their organisation.

This strategy lowers prices, reduces downtime, and promotes better service. Frequent failures can lead to elevated restore costs and potentially greater downtime costs. By bettering MTBF, an organization can cut back these costs significantly.